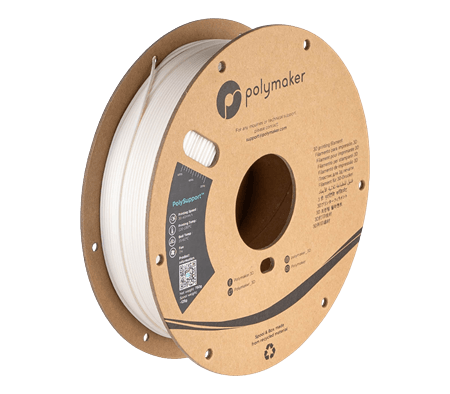

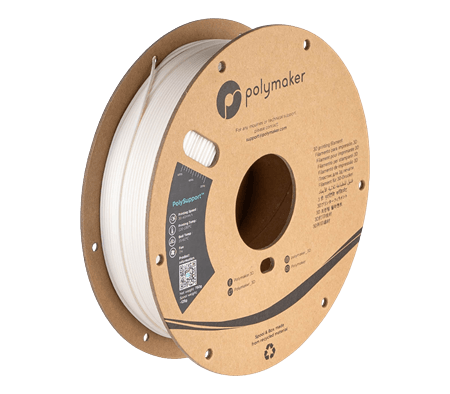

Polymaker

PolyMaker PolySupport for PLA 1.75mm 750g

PolyMaker PolySupport for PLA 1.75mm 750g

Out of stock

Couldn't load pickup availability

Dedicated easy break away support material for PLA, PVB & TPU filaments.

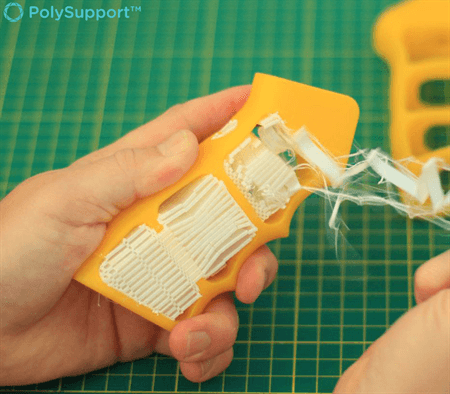

PolySupport™ is a break away support for a variety of Polymaker filaments. It has a perfect interface with PLA, strong enough to support it and easily removable by hand.

Features

-

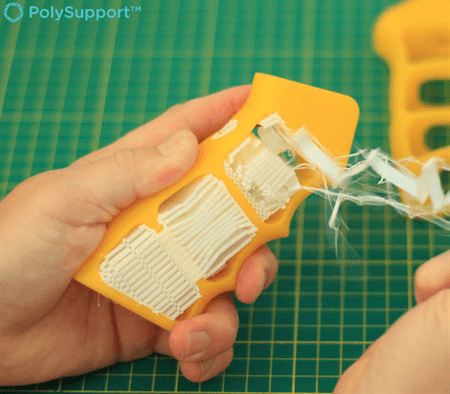

Peel Away - PolySupport™ is a dedicated support material engineered to break away easily by hand without the risk of damaging the part. PolySupport™ offers the quickest part clean-up of any support material. Its advantage over dissolvable support is that its faster to remove and requires no tools or equipment. For geometric overhangs such as boxes, architectural models or brackets, PolySupport™ will offer a better experience than dissolvable support.

-

Wide Material Support - PolySupport™ has been engineered to have excellent compatibility with PLA and depending on the part geometry it can be an ideal support material for PVB and TPU based filaments from Polymakers portfolio.

-

Low Moisture Sensitivity - PolySupport™ is less sensitive to moisture compared to other support materials like PVA and requires no solvents so you can immediately peel supports away without waiting for them to dissolve.

-

Improved surface quality - Improve the surface quality where supports interface with your prints when using PolySupport™.

-

Uncompromised Quality - Polymakers leading quality control process and rigorous in-house testing ensure reliable printing and consistency across spools and batches

The experience when removing supports can vary but with many designs and geometry it can be really difficult and time consuming to remove supports, sometimes requiring special tools to break supports away from the model. In many cases prints can fail due to support related issues.

Specifically engineered as a break away support material, PolySupport™ can be peeled away from 3D prints by hand, a huge bonus in educational environments and for businesses that don't have time to wait or equipment for supports to dissolve. Not only can supports be readily removed by hand but with PolySupport™ the bond between the supports and model is still strong enough to support overhangs while printing. It’s advantage over dissolvable support is that its faster to remove and requires no tools or equipment. For geometric overhangs such as boxes, architectural models or brackets, PolySupport™ will offer a better experience than dissolvable support.

When printing with PolySupport™ is is possible to print overhangs with comparable quality to what can be achieved with dissolvable supports. By printing with a high quality dual extrusion printer, suitable interface layer and no vertical offset between the model and supports, the PLA overhang will print directly onto the PolySupport™ interface layer, resulting in a very smooth underside surface. The break-away engineering behind PolySupport™ enables excellent adhesion between to the PLA model without over-adhesion. The result? Excellent underside surface quality and supports pillars which can still be easily removed by hand.

Blue part on the left: printed with a single extruder machine printing both supports and model in PLA (0.2mm z offset between support and model). Horizontal overhang displays visible scarring after supports are removed.

Red part on the right: printed on an Ultimaker S3 series 3D printer with PLA model and PolySupport supports (0mm z offset, zig zag supports and 1mm interface layers). No visible scarring on horizontal overhang, support removed cleanly.

Many users love PolySupport™ because it is also less sensitive to moisture when compared to soluble support filaments. This makes handling and storing PolySupport™ simple, just store the filament in the provided resealable bag when storing during long periods of time.

| Filament | |

| Diameter | 1.75mm |

| Spool Weight | 750g |

Printing Settings

| Nozzle Temperature | 220˚C – 230˚C |

| Build Surface material | Glass, blue tape BuildTak® |

| Build surface treatment | Can apply PVA glue to the build surface |

| Build plate temperature | 25˚C – 60˚C |

| Cooling fan | ON |

| Printing speed | 20mm/s – 40mm/s |

| Works best with | PLA materials from Polymakers portfolio |

Notes:

Drying Settings: 80˚C for 8h

Material CompatIbilities

PLA based material from Polymaker’s portfolio + +

PETG based material from Polymaker’s portfolio –

ABS based material from Polymaker’s portfolio –

PC based material from Polymaker’s portfolio +

PVB based material from Polymaker’s portfolio +

TPU based material from Polymaker’s portfolio +

Nylon based material from Polymaker’s portfolio – –

+ + support the model very well

+ generally support the model depending on its geometry

– generally doesn’t support the model depending on its geometry

– – do not support the model

Materials

Materials

PLA - This solid filament is used to make models that are a refined representation with rigid properties.

TPU - This flexible filament holds the shape of the model and can with stand being twisted and squashed to survive the field environment.

Shipping

Shipping

Free standard shipping and Express for free orders over $300 calculated at the checkout.

All items are shipped from Townsville, QLD.

Shipping World Wide - coming soon.

Care Instructions

Care Instructions

PLA

Temperature:

Keep it cool! PLA starts to soften at around 60°C (140°F), so avoid placing it near heat sources or leaving it in hot cars.

Sunlight:

Prolonged direct sunlight can cause fading and potential deformation. Try to keep it out of long sun exposures.

Cleaning:

Gently wash with warm water and a bit of mild soap using a soft cloth. No harsh scrubbing, please!

Handling:

Handle with care—avoid excessive bending or dropping it, as PLA is rigid and can crack or break.

Storage:

Store in a cool, dry place to maintain its shape and longevity.

TPU

Temperature:

TPU is built to be flexible, but still avoid extreme or prolonged heat. It’s more resilient than PLA, but unnecessary heat can still degrade it over time.

Sunlight:

Try not to leave TPU items in direct sunlight for too long, as UV rays can fade the colors and slowly affect the material quality.

Cleaning:

Just like PLA, a quick clean with warm water and mild soap works great. Use a soft cloth and don’t be too rough.

Handling:

Enjoy its flexibility! However, even though TPU can bend, continuous stretching or heavy impacts might wear it out faster.

Storage:

Keep it in a cool, dry spot away from harsh elements to maintain its flexibility and appearance.

Share