Polymaker

Polymaker PolySonic PLA Pro High Speed 1kg 1.75mm Filament

Polymaker PolySonic PLA Pro High Speed 1kg 1.75mm Filament

Out of stock

Couldn't load pickup availability

High-speed PLA+ filament with lightning-fast extrusion rate, cutting-edge precision, and exceptional layer adhesion developed for high-speed capable printers.

- High quality Polymaker High Speed PLA+ (PLA+ HS).

- Developed for consistent extrusion at high flow rates such as 22mm³/s at 230˚C.

- Better preservation of mechanical properties at high speed compared to PolyLite PLA Pro.

- Strong colour and consistent surface finish at high speeds.

- Rapid melting and fast cooling to switch from fluid to solid with minimal shrinkage.

- Consistent colour and tolerance (1.75mm diameter +/- 0.03mm)

Rapid 3D Printing with exceptionally durable high speed PLA+

With the steady development of high speed capable 3D printers, how quickly the filament can melt becomes a bottleneck for high flow extrusion. PolySonic™ PLA Pro is a tough PLA that can print at incredible speeds. With its advanced formulation, this filament ensures durable, rugged prints, with an impact strength similar to ABS and bending strength outperforming ASA & PETG. When time is of the essence for functional parts, PLA Pro is the ideal choice for you.

Features

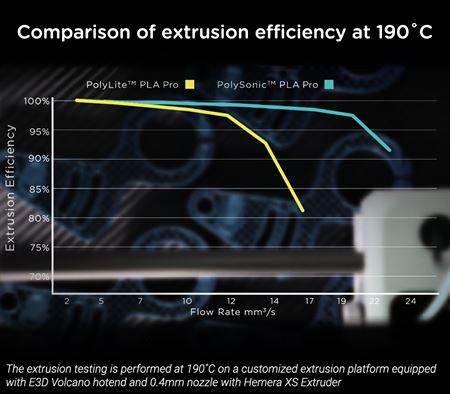

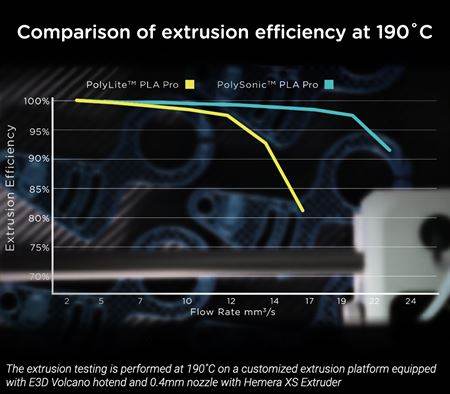

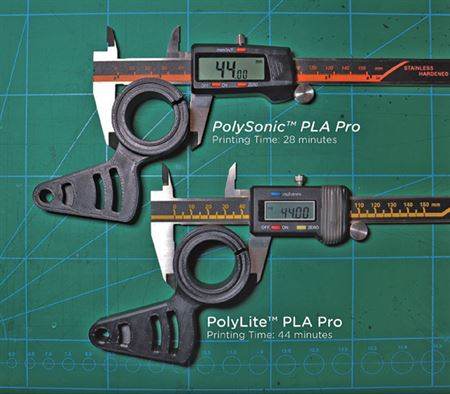

- High Flow Extrusion - PolySonic™ PLA Pro is a high speed toughness enhanced PLA+ developed to extrude consistently at high flow rates such as 22mm³/s on popular extrusion systems (equivalent to 275mm/s at 0.2mm layer height with a 0.4mm nozzle.). PolySonic™ PLA Pro exhibits a wider extrusion window when compared to many other PLA+ filaments, producing a 40% increase in flow rate at the same printing temperatures when compared to Polymakers original PolyLite™ PLA Pro formula. This boost in extrusion efficiency allows users to build profiles with higher printing speeds before noticing the effects of under-extrusion on the printed part.

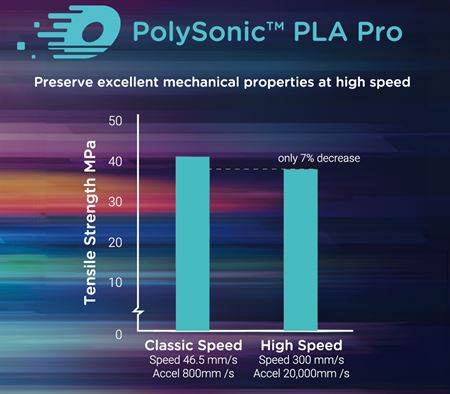

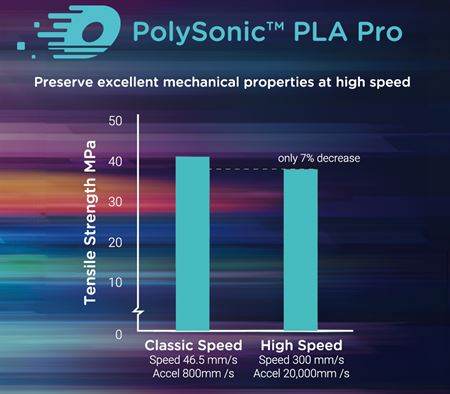

- Print Strong & Fast - PolySonic™ PLA Pro has been formulated to deliver an impact strength similar to ABS and bending strength that outperforms ASA & PETG without compromising on mechanical properties at high speed. PolySonic™ PLA Pro maintains approximately 90 - 95% of its mechanical properties when printing at high speed compared to the classic speed. PolySonic™ PLA Pro shows only a 7% drop in mechanical properties when printing at high speed compared to the classic speed. In contrast, PolyLite™ PLA+ Pro witnesses a 24% drop when the speed is increased. The consistent mechanical strength of PolySonic™ PLA Pro offers a high performance PLA+ for rapid prototyping and production.

- High Speed Accuracy - PolySonic™ PLA Pro can switch from fluid to solid with minimal shrinkage, producing crisp corners, fine details and smooth surfaces with no shark skin effect. PolySonic™ PLA Pro is not only capable of melting at high speeds but also cools quickly, allowing PolySonic™ PLA Pro to print rapidly. As the new generation of high-speed printers are equipped with auxiliary cooling, PolySonic™ is perfectly adapted to lightning printing speeds with rapid cooling characteristics.

- Consistent Melt & Finish - Developed for consistent and reliable high speed printing, PolySonic™ PLA Pro delivers a more consistent surface finish for layers printed at high or low speeds thanks to its excellent melt properties.

[1] Volumetric flow rate of 22mm³/s is equivalent to 275mm/s at 0.2mm layer height with a 0.4mm nozzle.

[2] Maximum flow rate can depend on the extrusion temperature. Polymakers maximum flow rate for PolySonic™ PLA Pro at 230˚C is 27mm³/s. Measurement of maximum flow is when extrusion decreases below 95% of the requested flow. Tested at 230˚C on a customised extrusion platform equipped with an E3D volcano hotend, 0.4mm nozzle with Hemera XS extruder. For a 0.4mm nozzle and 0.2mm layer height, 27mm³/s would be achieved with a 335mm/s printing speed. For a 0.4mm nozzle and 0.1mm layer height, 27mm³/s would be achieved with a 670mm/s printing speed.

[3] To achieve quality results, high-speed printing relies on both material and the 3D printer. Beyond material choice, quality and accuracy of a high speed print is also reliant on a high speed printer with well-tuned input shaping and pressure / linear advance.

Printing Settings

| Classic | High-speed | |

| Nozzle Temperature | 190°C - 210°C | 210°C - 230°C |

| Build Plate Temperature | 25°C - 60°C | |

| Build Surface Material | Works well with most build surfaces i.e Glass, Blue Tape, BuildTak® etc | |

| Build Surface Treatment | Can apply Magigoo Original or PVA glue to the build surface to improve adhesion. | |

| Cooling Fan | ON | ON + Auxiliary Fan (If available) |

| Printing Speed | 50 mm/s - 100 mm/s | 100 mm/s - 300 mm/s |

| Recommended Support Material |

Single Extrusion: |

The above are printing recommendations based on 0.4 mm nozzle. Please note ideal printing conditions may vary depending on your 3D printer setup. For high speed 3D printers, make sure to increase your extrusion temperature in order to use higher printing speeds.

For other tips printing PolySonic™ PLA Pro contact us!

Specification

| Net Weight | 1kg |

|---|---|

| Material Type | PLA+ (High Speed) |

| Melt Index (210°C, 2.16 kg) |

15.5 g/10min |

| Density | 1.23 (g/cm3 at 21.5˚C) |

Compatibility

PolySonic™ PLA Pro has been engineered for popular high-speed 3D printers and is capable of both high and classic 3D printing speeds.. High rigidity materials like PolySonic™ PLA Pro work best in set ups where the filament guide system is smooth and as no harsh bends.

Please note that Polymakers Jam-Free™ technology is not implemented into PolySonic™ PLA Pro. Jam-Free™ is a technology by Polymaker to improve compatibility with all metal hot end designs that suffer from heat creep. In this case, the exclusion of Jam-Free™ helps to ensure maximum melt-performance of the material. Many new high-speed printers have greatly improved hot-end designs so the risk of purchasing a high-speed machine that suffers from heat creep is much lower these days. If you own a regular printer that suffers from heat creep and has difficulty printing other brands of PLA due to jamming, we recommend using a different Polymaker PLA such as PolyLite™ PLA on that machine. This material is best suited for high-speed capable printers that don't suffer from heat creep.

Of course with thousands of unique 3d printer models on the market, we can't guarantee each filament type will work with every 3D printer. Slicer experience and setting adjustment is always required to get the most out of a material. Before jumping into an ambitious project we always recommend printing some known calibration tests to build or make adjustments to the filament profile.

Technical Data

All testing specimens were printed under the following conditions: build plate temperature = 45˚C, infil = 100%, cooling fan = ON

All specimens were conditioned at room temperature for 24h prior to testing.

THERMAL PROPERTIES

| Value | Testing Method | |

| Glass Transition | 61°C | DSC, 10°C/min |

| Heat Deflection Temperature |

0.45MPa - 55C HDT Curve |

ISO 75 |

| Vicat Softening Temperature | 61°C | ISO 306, GB/T 1633 |

MECHANICAL PROPERTIES

| Classic Speed [1] | High Speed [2] | Testing Method | |

| Youngs Modulus (X-Y) |

2,360.0 MPa | 2,305.7 MPa | ISO 527, GB/T 1040 |

| Tensile Strength (X-Y) |

41.2 MPa | 39.3 MPa | ISO 527, GB/T 1040 |

| Tensile Strength (Z) |

33.6 MPa | 31.9 MPa | ISO 527, GB/T 1040 |

| Bending Strength (X-Y) |

67.5 MPa | 64.1 MPa | ISO 178, GB/T 9341 |

| Charpy Impact Strength (X-Y) |

22.7 kJ/m2 | 19.4 kJ/m2 | ISO 179, GB/T 1043 |

[1] Based on 0.4 mm nozzle and 0.2mm layer thickness. Classic printing speed = 46.7mm/s, printing temperature = 210 °C

[2] Based on 0.4 mm nozzle and 0.2mm layer thickness. High printing speed = 300mm/s, printing temperature = 230 °C

We have full MDS and technical data sheets for PolySonic™ PLA Pro and all other Polymaker products. Contact us to enquire!

The typical values presented in Polymakers data sheet are intended for reference and comparison purposes only. Due to the nature of 3D printing they should not be used for design specifications or quality control purposes.

STORAGE & DRYING

All plastics are hygroscopic meaning they absorb moisture from the air which can affect printing quality and strength of printed parts. How quickly this absorption occurs depends on the material and your environment. Polymakers PolySonic™ PLA Pro filaments are dried and packaged in a vacuum sealed bag with desiccant to ensure the best printing quality. When not in use PolySonic™ PLA Pro should be stored away from sunlight and sealed in the packaged resealable bag.

Although filaments can be dried, drying will speed up the aging process of the plastic making it more brittle over time. Preventing the filament from absorbing moisture in the first place is the best solution to keep your filament working to its maximum potential. For long term storage we highly recommend storing in a sealed container with dry desiccant that reduces the relative humidity to 10-20% RH.

In-house we manage our filaments with Polymakers PolyDryer™ which keep offers best-in-class sealing to protect filaments from absorbing moisture

If you hear popping sounds and notice that the surface quality of your print is uneven or the colour is not consistent, this is a likely indicator that the filament has absorbed too much moisture. Spools of PolySonic™ PLA Pro can be dried with Polymaker PolyDryer™ using power level 1. Alternatively if you have a convection oven that is accurate at low temperatures, users can dry filament in a preheated convection oven at 55˚C for up to 6 hours. Results may vary depending on the accuracy of your oven so please be conservative. For more information about filament drying please read our user guide.

FAQ

Q: What makes PolySonic™ PLA Pro a high speed filament?

A: There are three crucial aspects which define PolySonic™ PLA as a high speed filament. Firstly it exhibits a higher extrusion window compared to regular PLA, producing a 30% increase in flow rate at the same printing temperatures when compared to regular PLA filaments. The second aspect is forming, PolySonic™ PLA Pro can transition from fluid to solid quickly with near-zero shrinkage. This produces crisp corners, fine details and steep overhangs while still extruding at high flow rates. The last aspect is the mechanical properties, many regular PLA's will show a significant drop in mechanical properties when printed at high speed. PolySonic™ PLA {rp shows only a 7% drop in mechanical properties when printing at high speed compared to the classic test specimen. In contrast, PolyLite™ PLA Pro witnesses a 24% drop when the speed is increased. This final factor allows PolySonic™ to print both fast and functional which has been the previous limitation to high-speed 3D printing.

Q: Does PolySonic™ PLA Pro feature Polymakers Jam-free technology?

A: No. To maximise the high flow performance, PolySonic™ PLA Pro does not feature the Jam-Free™ technology implemented in PolyLite™ PLA+ Pro and other Polymaker PLA filaments. Jam-Free™ technology is not as necessary for the printers it was designed for, many modern high-speed 3D printers have greatly improved hot-end designs with more efficient temperature control at the cold end of the extruder. As a result the risk of heat creep is much lower on modern-day high speed 3D printers.

Q: Should I rewind this filament if I want to use it with a different spool?

A: We strongly advise against tampering with the product by rewinding. See our article for full details about the risks. All Polymaker filaments are wound with tension but without strain. Rewinding completely rearranges the curvature of the winding and this strain over time can cause most plastics to catastrophically break. If for some reason your printer is locked into fitting less than standard sized spools, there may be safe printable adaptors or external mounting solutions available.

Don't know where to start? Or which filament will suit your application? We have a broad range of support options including telephone support. Contact us today!

| Filament | |

| Diameter | 1.75mm |

| Spool Weight | 1kg |

Materials

Materials

PLA - This solid filament is used to make models that are a refined representation with rigid properties.

TPU - This flexible filament holds the shape of the model and can with stand being twisted and squashed to survive the field environment.

Shipping

Shipping

Free standard shipping and Express for free orders over $300 calculated at the checkout.

All items are shipped from Townsville, QLD.

Shipping World Wide - coming soon.

Care Instructions

Care Instructions

PLA

Temperature:

Keep it cool! PLA starts to soften at around 60°C (140°F), so avoid placing it near heat sources or leaving it in hot cars.

Sunlight:

Prolonged direct sunlight can cause fading and potential deformation. Try to keep it out of long sun exposures.

Cleaning:

Gently wash with warm water and a bit of mild soap using a soft cloth. No harsh scrubbing, please!

Handling:

Handle with care—avoid excessive bending or dropping it, as PLA is rigid and can crack or break.

Storage:

Store in a cool, dry place to maintain its shape and longevity.

TPU

Temperature:

TPU is built to be flexible, but still avoid extreme or prolonged heat. It’s more resilient than PLA, but unnecessary heat can still degrade it over time.

Sunlight:

Try not to leave TPU items in direct sunlight for too long, as UV rays can fade the colors and slowly affect the material quality.

Cleaning:

Just like PLA, a quick clean with warm water and mild soap works great. Use a soft cloth and don’t be too rough.

Handling:

Enjoy its flexibility! However, even though TPU can bend, continuous stretching or heavy impacts might wear it out faster.

Storage:

Keep it in a cool, dry spot away from harsh elements to maintain its flexibility and appearance.

Share