Polymaker

Polymaker PolyMide PA612-CF Nylon 500g 1.75mm (Aka Fiberon PA612-CF15)

Polymaker PolyMide PA612-CF Nylon 500g 1.75mm (Aka Fiberon PA612-CF15)

Low stock: 1 left

Couldn't load pickup availability

Industrial carbon fiber reinforced copolymer of Nylon PA6 and PA12 / Features Polymakers Warp-Free™ and Fiber-Adhesion™ technology

PolyMide PA612-CF will transition to Polymakers Fiberon range and will be sold as Fiberon PA612-CF15 (same product, new name and packaging)

Fiberon is Polymakers new range of composite 3D printing filaments, launching in Q4 2024. Polymaker are transitioning PolyMide PA612-CF and their other PolyMide carbon-fiber / glass fiber reinforced Nylons and reintroducing them under the Fiberon product range.

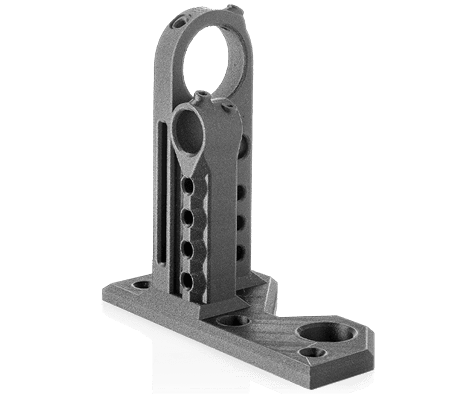

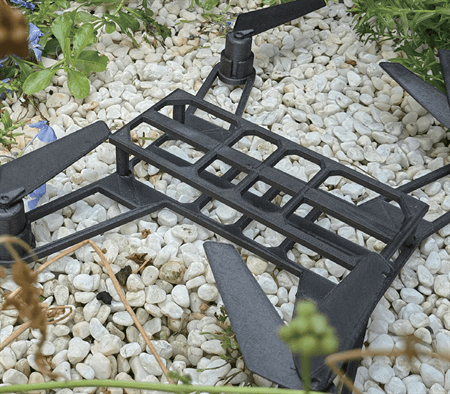

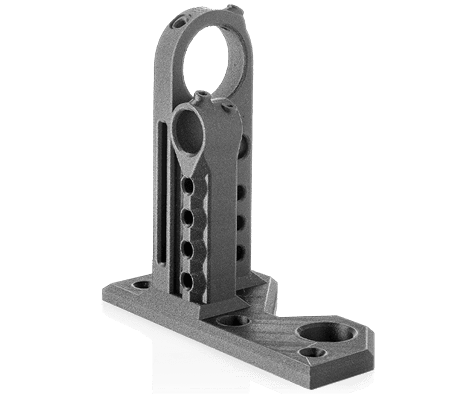

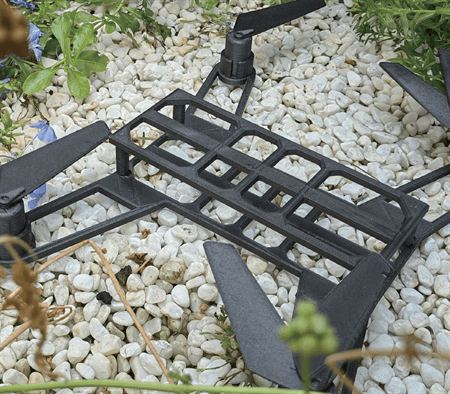

PolyMide™️ PA612-CF is a carbon fiber reinforced nylon filament based on a copolymer of Nylon 6 and Nylon 12. Featuring 15% chopped carbon fibers by weight, this filament has lower moisture sensitivity compared to PA6/66 and PA6-based materials, and better mechanical properties than PA12-based materials. Together with Polymaker's Warp-Free™ and Fiber-Adhesion™ technology, PolyMide™️ PA612-CF offers an optimal balance by combining the advantages of both PA6 and PA12 with optimised fiber reinforcement to deliver a high-performance filament with outstanding potential for industrial engineering, tooling, automotive, and end-use applications.

Features

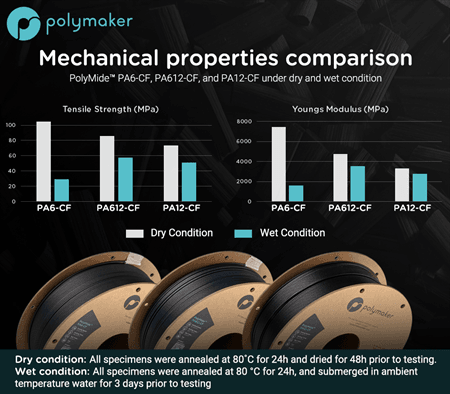

- Best of PA6 and PA12 - PolyMide™ PA612-CF is a copolymer combining PA6 and PA12 with 15% chopper carbon fiber to deliver high stiffness, tensile strength and heat resistance with lower moisture sensitivity. PolyMide™ PA612-CF offers the best middle ground between PA6 and PA12 and is a great-all-rounder for real-world applications that require the higher mechanical performance and affordability of short-chain nylon (PA6) with the reduced moisture sensitivity of long-chain nylon (PA12).

- Reduced Moisture Sensitivity - In most applications nylon parts absorb moisture from the air. The water molecule increases toughness and durability of the nylon while reducing strength and stiffness. PA6 is more susceptible to absorbing moisture than PA12 and as a result the mechanical properties of PA6 are effected in some application environments. PolyMide™ PA612-CF is less hygroscopic than PA6-CF making it an ideal and cost-effective alternative to PolyMide™ PA6-CF for parts which may be subject to high humidity.

- Excellent Heat Resistance - Featuring a high heat resistance after annealing[1], PolyMide™ PA612-CF offers excellent heat resistance for demanding applications where heat and stress are critical design factors.

- Outstanding Layer Adhesion - Most fiber reinforced materials show a decrease in z-axis layer adhesion when compared with their non-fiber reinforced Nylons, producing a part that is only stronger on the X-Y axis but detrimental to the Z axis. Polymakers Fiber Adhesion™ technology improves the layer adhesion of fiber reinforced materials, by optimising the surface chemistry of the fibers to achieve better dispersion and bonding to the matrix. The implementation of this technology in PolyMide™ PA612-CF not only solves this problem but actually increases Z axis tensile strength creating more isotropic parts that are strong in every direction.

- Warp-Free™ - Warp-Free™ technology enables the production of Nylon-based filaments that can be 3D printed with excellent dimensional stability and near-zero warpage. This is achieved by the fine control of microstructure and crystallisation behaviour of Nylon, which enables the material to fully release the internal stress before solidification. The Warp-Free™ technology in PolyMide™ PA612-CF is designed to work best with minimal bed temperatures.

- Excellent Printability – Unlike many other brands of Nylon filament, PolyMide™ PA612-CF is extremely easy to work with, exhibiting excellent dimensional stability during printing. It is compatible with most filament-based 3D printers capable of reaching 260°C nozzle temperature and no heated bed or chamber is required!

- Uncompromised Quality - Polymakers leading quality control process and rigorous in-house testing ensure reliable printing and consistency across spools and batches.

[1] PolyMide™ PA612-CF displays the best mechanical and thermal properties when fully crystallised. The printed part will not reach full crystallisation during the printing process, an additional step is required: Annealing. PolyMide™ PA612-CF can be annealed in the oven at 80˚C for 6 hours right after the printing process.

Technical Data

All PA612-CF specimens were printed with 300°C nozzle temperature, 50°C bed temperature, cooling fan OFF and samples were annealed after printing at 100°C for 16h. Samples were printed with 100% infil, 2 shells and 3 top & bottom layers.

FIBERON PA612-CF15 THERMAL PROPERTIES

| Value | Testing Method | |

| Heat Deflection Temperature |

0.45MPa - 175°C HDT Curve |

ISO 75 |

FIBERON PA612-CF15 MECHANICAL PROPERTIES

1. All Dry Status specimens were annealed at 100°C for 16h.

2. All Wet Status specimens were annealed at 100°C for 16h, and immerged in water at 60°C for 48h prior to testing. The

average moisture content of specimens is 2.57%

| Dry State Value | Wet State Value | Testing Method | |

| Youngs Modulus (X-Y) |

5136.7 ± 192.2 MPa | 3990.8 ± 136.5 MPa | ISO 527, GB/T 1040 |

| Youngs Modulus (Z) |

2786.4 ± 78.4 MPa | 2386.8 ± 150.2 MPa | |

| Tensile Strength (X-Y) |

91.9 ± 2.0 MPa | 83.1 ± 2.2 MPa | ISO 527, GB/T 1040 |

| Tensile Strength (Z) |

48.3 ± 3.9 MPa | 35.6 ± 3.0 MPa | |

| Bending Strength (X-Y) |

138.0 ± 2.2 MPa | 118.1 ± 1.6 MPa | ISO 306, GB/T 1633 |

| Charpy Impact Strength Notched (X-Y) |

8.1 ± 0.8 kJ/m2 | 7.7 ± 0.5 kJ/m2 | ISO 179, GB/T 9343 |

Data taken from Polymakers Technical Data Sheet and is intended for reference and comparison purposes only. Due to the nature of 3D printing, data should not be used for design specifications or quality control purposes.

Printing Settings

| Nozzle Temperature | 250°C - 300°C |

|---|---|

| Build Plate Temperature | 25°C - 50°C* *Do not exceed 50°C! |

| Build Surface Material | Compatible with most common build surfaces. Apply a thin layer of glue stick to the build plate. |

| Build Surface Treatment | PVA or PVP glue stick. |

| Cooling Fan | OFF |

| Printing Speed | 30 mm/s - 60 mm/s |

| Retraction | The ideal retraction settings vary from printer to printer and depend on the hot end. The following settings have been a good starting point for many machines. Direct Drive: Retraction distance of 3mm with retraction speed of 50mm/s Bowden: Retraction distance of 6mm with retraction speed of 60mm/s |

| Enclosure | Not required but useful to protect from drafts and maintain a stable printing environment. |

| Heated Chamber | Not recommended. |

| Recommended Support Material | Single Extrusion: Self Support If PolyMide™ PA612-CF is used as the support material for itself, please remove the support structure before excessive moisture absorption. Otherwise the support structure can be permanently bonded to the model. Dual Extrusion: PolySupport™ for PA12 (Breakaway) |

The above are printing recommendations based on 0.4 mm nozzle. Please note ideal printing conditions may vary depending on your 3D printer setup. For high speed 3D printers, make sure to increase your extrusion temperature in order to use higher printing speeds.

Hardened nozzles such as hardened steel are less conductive than brass, so depending on your 3D printer, printing with a higher extrusion temperature may be required when using a wear resistant nozzle.

We highly recommend to use a wear resistant nozzle when printing PolyMide™ PA612-CF. Hardened steel offers much better wear resistance than brass. The second consideration when printing Nylon is protection from moisture. See "Storage and Drying" details below for instructions to protect PolyMide™ PA612-CF.

Specific Printing Tips for PolyMide™ PA612-CF

- PolyMide™ PA612-CF is a very stiff filament. When not in use, please use tape to secure the filament tip to the spool the rather than attempting to bend the filament through the spool guide hole. During printing it is required to have a smooth feeding path to ensure optimal feeding. For example we recommend avoiding excessive bending in the filament guide system.

- Unlike other Nylon filaments which are notorious for warping, PolyMide™ PA612-CF has been formulated to print easily without a heated build plate or enclosure. Additional heat is not beneficial to the printing process so if you are using an industrial 3D printer we highly recommend turning off the heated chamber and not exceeding 50°C build plate temperature.

- PolyMide™ PA612-CF can easily damage a brass nozzle after a few hundred grams of printing. Nozzles come in many different materials from soft to hard and the heat conductivity of a nozzle can change depending on what material it is made of. Hardened steel is more abrasion resistance than brass or a nickel plated nozzle.

- Inter-layer strength can depend significantly on your extrusion temperature which is a result of your printing speed, nozzle type and hot end. A higher nozzle temperature / extrusion temperature can offer significant benefits in regards to inter-layer strength. When printing PolyMide™ PA612-CF at low temperature (250-260 ˚C) on a general desktop 3d printer, it is recommended to use a hardened nickel-coated brass nozzle which offers better thermal conductivity than hardened steel.

Annealing Nylon PA612

For the best mechanical performance it is highly recommended to anneal parts printed in PolyMide™ PA612-CF. Annealing is the process of heating up the printed parts at a certain temperature for a certain period of time. PolyMide™ PA612-CF displays outstanding mechanical and thermal properties when fully crystallised. The printed part will not reach full crystallisation after the printing process and annealing shortly after the printing process is required to complete this step.

Annealing Settings - 100˚C for 16 hours.

Here's some data below of how properties of PA612-CF vary

|

Before Annealing |

After Annealing (80˚C for 24 hours) |

After Annealing (100˚C for 16 hours) |

Performance Change | |

| Tensile Strength (X-Y) |

60.6 ± 0.27 | 86.1 ± 1.0 | 91.9 ± 2.0 |

+42% increase |

| Young's Modulus (X-Y) |

3364.6 ± 174.0 | 4735.7 ± 87.9 | 5136.7 ± 192.2 |

+40% increase |

| Bending Strength (X-Y) |

88.3 ± 1.8 | 125.1 ± 2.6 | 138.0 ± 2.2 |

+41.6% increase |

| Heat Resistance (HDT @ 1.8 MPa) |

55˚C | 114˚C | 114˚C |

+109% increase |

Specification

| Net Weight | 500g |

|---|---|

| Material Type | Copolymer of Nylon 6 and Nylon 12 |

| Density | 1.03 g/cm3 |

| Colour | Black |

Compatibility

PolyMide™ PA612-CF has been engineered so users can print strong carbon fiber filled parts with excellent layer-adhesion. As the carbon fiber in this material is highly abrasive we recommend customers first check that their 3D printer is equipped to print abrasive materials before purchasing this product.

Aside from wear resistance, there are a few important considerations for this material that we recommend.

Reinforced filaments tend to be much stiffer than other standard filaments and this can cause problems when passing the filament through a printer’s feeding system. For a steady and uninterrupted flow of filament, it is recommended to take extra care and make sure your filament guide system is smooth and with minimal bends. Brass nozzles give a better thermal conductivity than hardened nozzles such as stainless steel. Depending on your 3D printer, printing with higher extrusion temperatures may be required when using specialty nozzles to ensure the correct extrusion temperature is achieved.

Of course with thousands of unique 3d printer models on the market, we can't guarantee each filament type will work with every 3D printer.

Technical Data

We have full MDS and technical data sheets for Fiberon™ PA612-CF15 (aka PolyMide PA612-CF) and all other Fiberon filaments from Polymaker. Contact us to enquire!

The typical values presented in Polymakers data sheet are intended for reference and comparison purposes only. Due to the nature of 3D printing they should not be used for design specifications or quality control purposes.

STORAGE & DRYING

Nylon filaments are very hygroscopic meaning they quickly absorb moisture from the air which can affect printing quality and strength of printed parts. Before packaging, PolyMide™ PA612-CF is dried to ensure the best printing quality and filaments are vacuum sealed in a resealable mylar bag to protect the filament from moisture.

- When opening, carefully open the resealable bag, remove the spool and close the bag back to preserve the desiccant bag.

- Print PolyMide PA612-CF from a dry box with a 10 - 15% RH which will protect the filament from absorbing moisture. We recommend Polymaker PolyBox™ which uses desiccant to keep the filament at dry conditions (relative humidity of 15% or less) without using heat. Dry boxes with a heating element can degrade plastic filaments if used extensively.

- After the print is completed, PolyMide™ PA612-CF can be stored in the PolyBox™, be sure to monitor and maintain the desiccant to keep RH below 15% RH. If a PolyBox™ is not being used the filament can be resealed in the resealable bag at the end of the print. In both situations it's recommended to store the filament away from sunlight for long term storage and replace / dry the desiccant as required.

These recommendations are ultimately to prevent the filament from absorbing moisture in the first place. If you hear popping sounds and notice that the surface quality of your print is uneven or the colour is not consistent, this is a likely indicator that the filament has absorbed too much moisture and can be remedied. Spools of PolyMide™ PA612-CF can be dried in a preheated convection oven at 80˚C for up to 12 hours.

Although drying is a suitable solution it's highly recommended not to excessively dry the filament and instead take precautions to prevent moisture absorption. Continually drying any plastic can make it more brittle and storing filament long term with moisture content can cause filaments to become more brittle due to hydrolysis.

FAQ

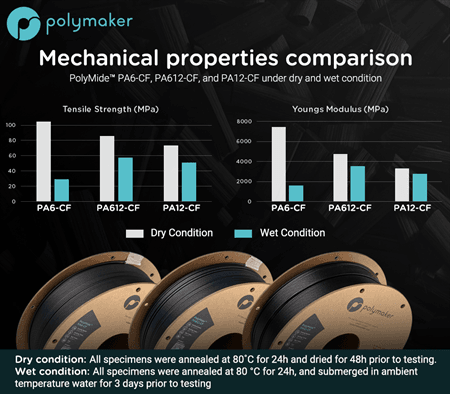

Q: What is the "Dry" state vs "Wet" state?

A: Nylon 6 and Nylon 12 materials absorb moisture not only as a filament but also the final printed part, we call this process moisture conditioning. The "Dry" state is the printed part immediately after annealing and the "Wet" state represents the mechanical properties after absorbing moisture from the air, there is a third state "Saturated" which represents the properties if the material is submerged in water. As the printed part absorbs moisture, it will become more flexible and impact resistant, seeing a decrease in rigidity and tensile strength when compared to its dry state.

Shorter chain nylons such as PA6 or PA6,6 are capable of absorbing more moisture compared to longer-chain nylons such as PA11 and PA12, thus longer-chain nylons show a smaller shift in characteristics between dry and wet state and shorter-chain nylons show a greater change. PA612 is an excellent middle ground offering higher mechanical performance than PA12 with lower moisture sensitivity than PA6 or PA6,6. As with all nylon plastics, it is generally assumed that PolyMide™ PA612-CF 3D prints will eventually reach their "Wet" state however there are numerous cases where the part may never become moisture conditioned. Examples include components operating in a high temperature environment, 3D prints that have been post-processed and protected with a moisture barrier or perhaps for applications where the PolyMide™ PA612-CF is submerged in a specific chemical or oil.

Q: Can I print this material without wear resistant hardware (nozzle etc.)?

A: PolyMide™ PA612-CF contains 15% chopped carbon fibers by weight which makes it very abrasive. It is important to have an abrasion resistant nozzle and hardware when printing this material. PolyMide™ PA612-CF can easily damage a brass nozzle after a few hundred grams of printing. Hardened nozzles are more expensive than regular brass nozzle so it is important to consider the amount of materials planned to be used. For some users it may be more cost effective to destroy one nozzle for some prints, but please note users are responsible for all printer 'wear and tear'.

Q: How well does Polymakers Warp-Free™ technology perform?

A: With Polymakers Warp-Free technology, more users can effectively print PA612-CF with better dimensional stability than comparative nylon products. This technology works best when printing with low bed/chamber temperatures. Because the warping behaviour of Nylon materials is partially related to its crystallization rate while printing. If a user does print with a high temperature heated bed or chamber, the heat will increase the crystallization rate and cause a part to warp.

Q: Is annealing PolyMide™ PA612-CF required?

A: After printing, annealing PolyMide™ PA612 prints will ensure the highest degree of crystallinity. This is a recommended step as it allows end users to get the best properties and performance from their parts. PolyMide™ PA612 can be annealed in a convection oven at 80˚C for 6 hours. Of course annealing may not be required for applications that don't require the best thermal or mechanical properties. In some rare cases with fine or thin geometries, different annealing instructions or design considerations may be required for the best results.

Q: Will this filament absorb moisture?

A: Yes, Polyamides are hygroscopic, meaning that they absorb moisture from the air. Some grades are more sensitive to moisture than others but regardless it's important to keep all nylon filaments dry for the best printing process. Polymaker nylon filaments are dried from the factory to ensure customers can achieve excellent results straight away, we recommend keeping your spool of PolyMide™ PA612-CF dry as moisture can significantly reduce mechanical properties and cause print defects such as oozing and poor surface quality. To prevent moisture absorption in your filaments, it is recommended to use the PolyBox™ which provides a stable, low level humidity storage solution for filaments during and in-between printing. If PolyMide™ PA612-CF appears to have absorbed too much moisture, they can be dried in a preheated convection oven for 12 hours at 80˚C.

Q: Is PolyMide™ PA612-CF suitable for high humidity or "wet" applications?

A: PolyMide™ PA612-CF strikes the best balance between the high performance of PA6-CF and the low moisture sensitivity of PA12-CF without breaking the bank. Submerged parts in PolyMide™ PA612-CF will perform better than those printed in PA6-CF with better strength, stiffness and dimensional stability, making it a suitable choice for real-world applications. PolyMide™ PA12-CF absorbs the least amount of moisture, so depending on the application it may still be best to choose PolyMide™ PA12-CF.

Q: What support materials can I use with this product?

A: On multi-material printers it's recommended to print with Polymaker’s PolySupport™ for PA12, a dedicated break away support material for Polymakers long-chain nylon filaments. PolySupport™ for PA12 works best for 3D printing geometric models such as jigs and fixtures or covering parts since PolySupport™ for PA12 will be removed faster and more easily than a dissolvable support.

Q: Should I rewind this filament if I want to use it with a different spool?

A: We strongly advise against tampering with the product by rewinding. See our article for full details about the risks. All Polymaker filaments are wound with tension but without strain. Rewinding completely rearranges the curvature of the winding and this strain over time can cause most plastics to catastrophically break. If for some reason your printer is locked into fitting less than standard sized spools, there may be safe printable adaptors or external mounting solutions available.

Materials

Materials

PLA - This solid filament is used to make models that are a refined representation with rigid properties.

TPU - This flexible filament holds the shape of the model and can with stand being twisted and squashed to survive the field environment.

Shipping

Shipping

Free standard shipping and Express for free orders over $300 calculated at the checkout.

All items are shipped from Townsville, QLD.

Shipping World Wide - coming soon.

Care Instructions

Care Instructions

PLA

Temperature:

Keep it cool! PLA starts to soften at around 60°C (140°F), so avoid placing it near heat sources or leaving it in hot cars.

Sunlight:

Prolonged direct sunlight can cause fading and potential deformation. Try to keep it out of long sun exposures.

Cleaning:

Gently wash with warm water and a bit of mild soap using a soft cloth. No harsh scrubbing, please!

Handling:

Handle with care—avoid excessive bending or dropping it, as PLA is rigid and can crack or break.

Storage:

Store in a cool, dry place to maintain its shape and longevity.

TPU

Temperature:

TPU is built to be flexible, but still avoid extreme or prolonged heat. It’s more resilient than PLA, but unnecessary heat can still degrade it over time.

Sunlight:

Try not to leave TPU items in direct sunlight for too long, as UV rays can fade the colors and slowly affect the material quality.

Cleaning:

Just like PLA, a quick clean with warm water and mild soap works great. Use a soft cloth and don’t be too rough.

Handling:

Enjoy its flexibility! However, even though TPU can bend, continuous stretching or heavy impacts might wear it out faster.

Storage:

Keep it in a cool, dry spot away from harsh elements to maintain its flexibility and appearance.

Share