Polymaker

Polymaker PolyMide PA6-CF Nylon Carbon Fiber Black 1.75mm 2kg

Polymaker PolyMide PA6-CF Nylon Carbon Fiber Black 1.75mm 2kg

Out of stock

Couldn't load pickup availability

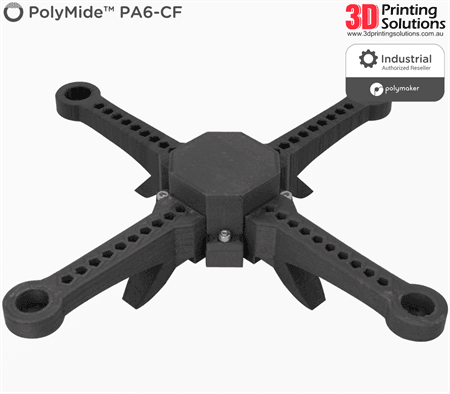

Industrial carbon-fiber reinforced Nylon 6 delivers best-in-class stiffness and mechanical performance and is suitable for a wide range of high performance applications requiring torsional, tensile and impact strength.

- Carbon-fiber reinforced Nylon 6 combines excellent mechanical performance with vastly improved stiffness & heat resistance.

- Reinforced with 20% chopped fibers delivering excellent tensile layer-adhesion, stiffness and high strength to weight ratio.

- The best strength and stiffness among Polymaker Nylon products in "dry state".

- High heat resistance up to 215℃ HDT (0.45 MPa) after annealing.

- Carbon-fiber reinforcement offers some ESD safe properties.

- Excellent dimensional stability during printing.

- Cardboard spool & packaging (made from 100% recycled cardboard)

PolyMide PA6-CF will transition to Polymakers Fiberon range and will be sold as Fiberon PA6-CF20 (same product, new name and packaging). The large spools will be 3kg as opposed to the 2kg spool and priced accordingly.

Fiberon is Polymakers new range of composite 3D printing filaments, launching in Q4 2024. Polymaker are transitioning PolyMide PA6-CF and their other PolyMide carbon-fiber / glass fiber reinforced Nylons and reintroducing them under the Fiberon product range.

PolyMide™ is a family of Nylon/polyamide based filaments. Produced with Polymaker’s Warp-Free™ technology, PolyMide™ filaments deliver engineering properties intrinsic to Nylon and ease of printing.

PolyMide™️ PA6-CF is a carbon fiber reinforced nylon filament featuring 20% chopped carbon fibers by weight. Within Polymakers range of nylon filaments, PolyMide™ PA6-CF delivers best in class stiffness, strength and heat resistance and superior z axis tensile strength to outperform many other functional 3D printing materials in "dry state". Together with 20% industrial chopped carbon fibers, Polymakers Fiber-Adhesion™ technology optimizes the surface chemistry of the fibers to achieve better dispersion and bonding to the Nylon 6 matrix and delivers an outstanding filament for functional applications..

Features

- Excellent Stiffness & Strength - Featuring a tensile modulus up to 7.4 GPA on the XY axis and 4.3 GPA on the Z axis, PolyMide™ PA6-CF is well suited for high performance industrial and engineering applications. PolyMide™ PA6-CF combines extreme stiffness and best-in-class tensile strength. PolyMide™ PA6-CF is an excellent choice for dry applications[1] requiring stiffness and durability such as automotive brackets, jigs, ESD safe fixtures, aerospace, prosthetics and engineering.

- Excellent Heat Resistance - Featuring a high heat resistance up to 215°C after annealing[2], PolyMide™ PA6-CF offers excellent heat resistance for demanding applications where heat and stress are critical design factors. This material lends itself perfectly to functioning automotive applications where a combination of heat resistance and mechanical properties are required.

- Outstanding Layer Adhesion - Most fiber reinforced materials show a decrease in z-axis layer adhesion when compared with their non-fiber reinforced Nylons, producing a part that is only stronger on the X-Y axis but detrimental to the Z axis. Polymakers new technology in PolyMide™ PA6-CF not only solves this problem but actually increases Z axis tensile strength creating more isotropic parts that are strong in every direction.

- Warp-Free™ - PolyMide™ PA6-CF features Polymakers Warp-Free™ technology to deliver a reliable Nylon filament with excellent dimensional stability and near-zero warpage. This is achieved by the fine control of microstructure and crystallization behaviour of Nylon, which enables the material to fully release the internal stress before solidification. The Warp-Free™ technology in PolyMide™ PA6-CF is designed to work best with minimal bed temperatures.

- Wear Resistant and Tough - Parts printed in PolyMide™ PA6-CF display excellent toughness and wear resistant properties.

- ESD Safe - PolyMide™ PA6-CF is an ESD safe material making it a suitable candidate for printing electronic jigs and fixtures

- Improved Printability – Unlike many other Nylon filaments, PolyMide™ PA6-CF is extremely easy to work with, exhibiting excellent dimensional stability. It is compatible with most filament-based 3D printers with no heated bed or chamber required!

- Uncompromised Quality - Polymakers leading quality control process and rigorous in-house testing ensure reliable printing and consistency across spools and batches.

[1] Most Nylon parts in the real world undergo a process called "Moisture conditioning" which improves toughness and flexibility of the Nylon while reducing tensile strength and stiffness. Unless protected with a moisture barrier, PA6-CF shows a greater change in mechanical properties when subjected to water / high humidity in comparison to long-chain nylon filaments like PA12-CF or PA612-CF. In simple terms PA6-CF will typically offer the best properties in a dry application, but for a wet or high humidity application a longer chain nylon such as PA612 or PA12 may be better. See "Specifications & FAQ" tab to learn more about what moisture conditioning is, how it works and if it's relevant to your application.

[2] PolyMide™ PA6-CF displays the best mechanical and thermal properties when fully crystallized. The printed part will not reach full crystallization during the printing process, an additional step is required: Annealing. PolyMide™ PA6-CF can be annealed in the oven at 80˚C for 6 hours right after the printing process.

Nylon also known as Polyamide (PA) is one of the most popular engineering grade plastics used across a wide range of industries. Nylon 6 is an excellent matrix material for composites like carbon fiber which enhance stiffness, strength and heat resistance.

When compared to other Nylon 6 carbon fiber filaments, PolyMide™ PA6-CF offers some significant advantages.

- Best stiffness, strength, toughness and wear resistance.

- Excellent heat resistance (215°C).

- Outstanding layer adhesion (Fiber Adhesion™ technology)

- Outstanding dimensional stability when compared to other Nylon materials (Warp-Free™ technology)

Carbon fiber reinforcement provides significant stiffness, tensile strength and improved layer ahdesion with Polymakers Fiber adhesion™ technology.

Carbon fiber filled nylon materials suffer from poor layer-adhesion; losing up to 40% of their z axis tensile strength when compared with unreinforced nylon. To solve this issue, Polymaker exclusively developed their Fiber adhesion™ technology, which optimizes the surface chemistry of the fibers to achieve better dispersion and bonding to Nylon 6, resulting in improved layer adhesion when compared to unreinforced nylon.

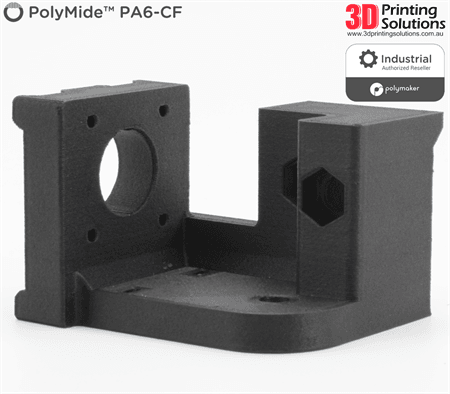

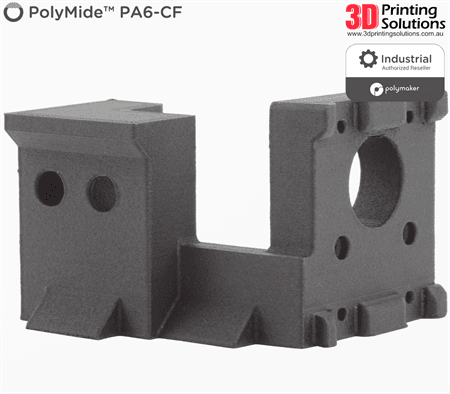

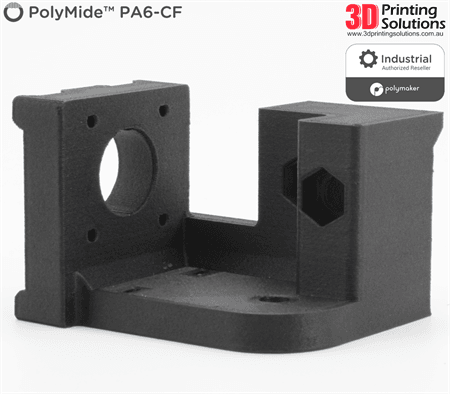

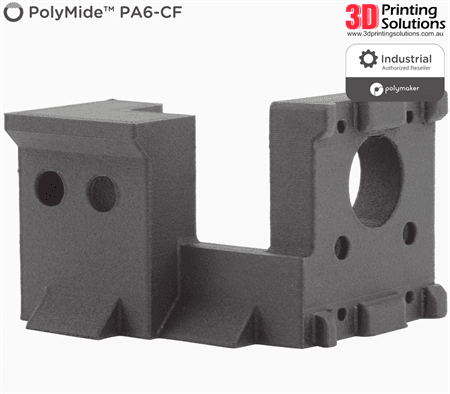

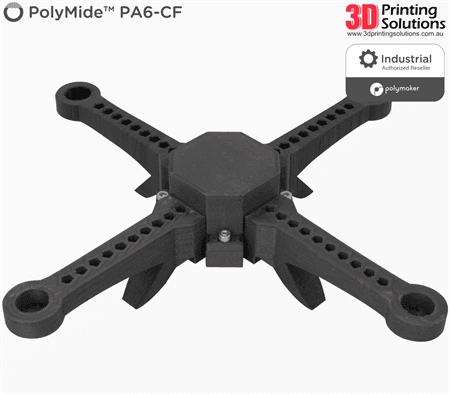

Bracket 3D printed in PolyMide™ PA6-CF

Combined with Polymakers Warp-free™ technology, manufacturers can reliably print more isotropic and dimensionally accurate parts with PolyMide™ PA6-CF without requiring a heated bed or chamber.

The carbon fiber reinforcement provides significantly improved stiffness, ESD protection, strength and heat resistance without affecting z-axis layer adhesion. Featuring a heat deflection temperature of up to 215°C, this material lends itself perfectly to research, aerospace, automotive, and manufacturing industries where strength and heat resistance are required.

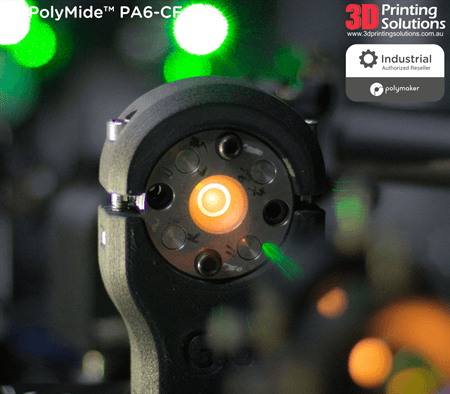

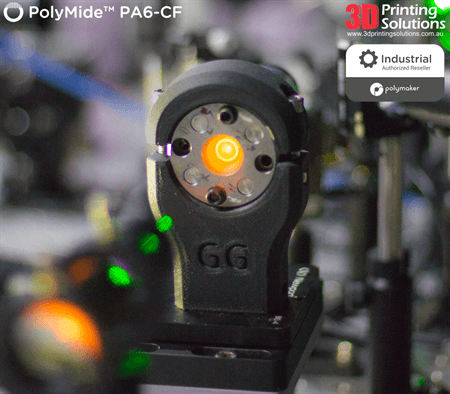

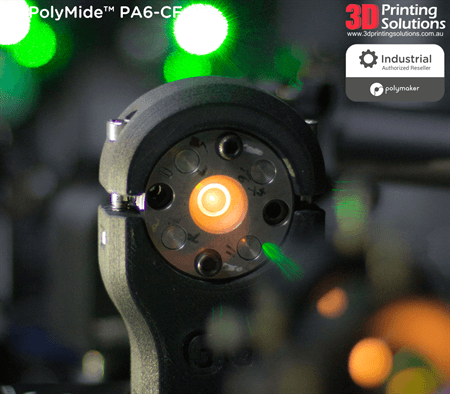

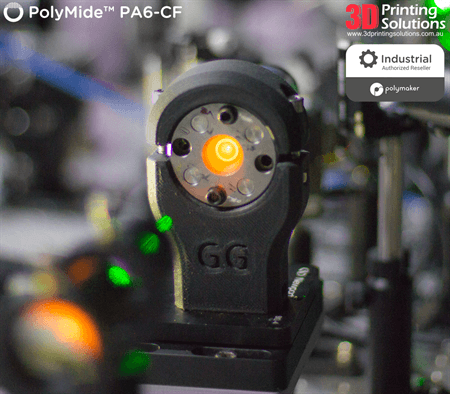

HP Star scientists utilize PolyMide™ PA6-CF for custom lab equipment.

HP Star is a high-pressure research laboratory investigating environments that mimic conditions found at the core of our solar system’s largest planets.

PolyMide™ PA6-CF is their material of choice to 3D print cell holders containing cells which provide significant clamping force. The material requirements for these cell holders are very demanding as the localised pressure and temperature within the chamber can reach 400 GPa and over 3800°C. While this immense pressure and temperature is very localised within the cells and only occurs for a short period of time, the material of the cell holders still needs to be very rigid and heat resistant to produce reliable experiments. With PolyMide™ PA6-CF, HP star can 3D print incredibly stiff, superior and more formative lab equipment which would otherwise require a 2 - 3 week lead time to manufacture.

Door Handle for LSEV Electric Car

PolyMide™ PA6-CF is one of few high temperature industrial materials that can be 3D printed at large scales without a heated bed or chamber. XEV are an automotive manufacturer utilizing Polymakers warp-free™ technology to 3D print all visible parts of the car aside from the chassis, seats and glass in Polymakers PolyMide™ family of materials. With 3D printing, XEV have reduced the number of components in their car from 2,000 down to 57 and have cut development costs by 90% and development time by 70%.

XEV are using PolyMide™ PA6-CF to print parts which require excellent stiffness like the the door handle. To overcome to complexity of these parts, XEV print the door handles with soluble supports using PolyDissolve™ S1, a dedicated soluble support material which bonds and interfaces perfectly with PolyMide™ PA6-CF. PolyDissolve™ S1 is engineered to bond with a wide variety of filament types from Polymakers portfolio.

Printing Settings

| Nozzle Temperature | 280°C - 300°C |

|---|---|

| Build Plate Temperature | 25°C - 50°C* *Do not exceed 50°C! |

| Build Surface Material | Compatible with most common build surfaces. Apply a thin layer of glue stick to the build plate. |

| Build Surface Treatment | PVA or PVP glue stick. |

| Cooling Fan | OFF |

| Printing Speed | 30 mm/s - 60 mm/s |

| Retraction | The ideal retraction settings vary from printer to printer and depend on the hot end. The following settings have been a good starting point for many machines. Direct Drive: Retraction distance of 3mm with retraction speed of 50mm/s Bowden: Retraction distance of 6mm with retraction speed of 60mm/s |

| Enclosure | Not required but useful to protect from drafts and maintain a stable printing environment. |

| Heated Chamber | Not recommended. |

| Recommended Support Material | Single Extrusion: Self Support If PolyMide™ PA6-CF is used as the support material for itself, please remove the support structure before excessive moisture absorption. Otherwise the support structure can be permanently bonded to the model. Dual Extrusion: PolyDissolve™ S1* *Please note that PA6-CF will absorb water during the dissolving process, not ideal for applications requiring specific dimensional accuracy. |

Based on 0.4 mm nozzle. Printing conditions may vary with different printers higher speeds / flow rates and nozzle diameters. Brass nozzles give a better thermal conductivity than hardened nozzles such as hardened steel so depending on your 3D printer, printing with a higher extrusion temperature may be required when using specialty nozzles to ensure the correct extrusion temperature is achieved.

Unlike other Nylon filaments which are notorious for warping, PolyMide™ PA6-CF has been formulated to print easily without a heated build plate or enclosure. Additional heat is not beneficial to the printing process so if you are using an industrial 3D printer we highly recommend turning off the heated chamber and not exceeding 50°C build plate temperature.

We highly recommend to use a wear resistant nozzle when printing Polymide™ PA6-CF. The second consideration when printing Nylon is protection from moisture. See "Storage and Drying" details below for instructions to protect PolyMide™ PA6-CF.

Annealing Nylon PA612

For the best mechanical performance it is recommended to anneal parts printed in PolyMide™ PA6-CF. Annealing is the process of heating up the printed parts at a certain temperature for a certain period of time. PolyMide™ PA6-CF displays outstanding mechanical and thermal properties when fully crystallized. The printed part will not reach full crystallization after the printing process and annealing shortly after the printing process is required to complete this step.

Annealing Settings - 80˚C for 6 hours.

Specification

| Net Weight | 2kg |

|---|---|

| Material Type | Nylon 6 with 20% chopped carbon fiber |

| Density | 1.17 g/cm3 |

| Colour | Black |

Compatibility

PolyMide™ PA6-CF has been engineered so users can print strong carbon fiber filled parts with excellent layer-adhesion. As the carbon fiber in this material is highly abrasive we recommend customers first check that their 3D printer is equipped to print abrasive materials before purchasing this product.

Aside from wear resistance, there are a few important considerations for this material that we recommend.

Reinforced filaments tend to be much stiffer than other standard filaments and this can cause problems when passing the filament through a printer’s feeding system. For a steady and uninterrupted flow of filament, it is recommended to take extra care and make sure your filament guide system is smooth and with minimal bends. Brass nozzles give a better thermal conductivity than hardened nozzles such as stainless steel. Depending on your 3D printer, printing with higher extrusion temperatures may be required when using specialty nozzles to ensure the correct extrusion temperature is achieved.

Of course with thousands of unique 3d printer models on the market, we can't guarantee each filament type will work with every 3D printer.

Technical Data

All testing specimens were printed under the following conditions: nozzle temperature = 300˚C, cooling fan = OFF, build plate temperature = 45˚C, infil = 100%, environmental temperature = 25 - 50˚C

All specimens were annealed prior to testing.

THERMAL PROPERTIES

| Value | Testing Method | |

| Glass Transition Temperature | 74.2°C | DSC, 10°C/min |

| Heat Deflection Temperature 0.45 MPa | 215°C |

ISO 75 0.45MPa |

| Heat Deflection Temperature 1.8 MPa | 173°C | ISO 75 1.8MPa |

| Vicat Softening Temperature | N/A | ISO 306, GB/T 1633 |

DRY STATE MECHANICAL PROPERTIES

All specimens were annealed at 80˚C for 24h and dried for 48h prior to testing.

| Value | Testing Method | |

| Youngs Modulus (X-Y) |

7,453 MPa | ISO 527, GB/T 1040 |

| Tensile Strength (X-Y) |

105 MPa | ISO 527, GB/T 1040 |

| Tensile Strength (Z) |

67.7 MPa | ISO 527, GB/T 1040 |

| Bending Strength (X-Y) |

169 MPa | ISO 178, GB/T 9341 |

| Charpy Impact Strength (X-Y) |

13.34 kJ/m2 | ISO 179, GB/T 9343 |

MOISTURE CONDITIONED MECHANICAL PROPERTIES

All specimens were annealed at 80˚C for 24h and moisture conditioned.

| Value | Testing Method | |

| Youngs Modulus (X-Y) |

5,666 MPa | ISO 527, GB/T 1040 |

| Tensile Strength (X-Y) |

81.7 MPa | ISO 527, GB/T 1040 |

| Tensile Strength (Z) |

64.4 MPa | ISO 527, GB/T 1040 |

| Bending Strength (X-Y) |

152.2 MPa | ISO 178, GB/T 9341 |

| Charpy Impact Strength (X-Y) |

32.8 kJ/m2 | ISO 179, GB/T 9343 |

We have full MDS and technical data sheets for PolyMide™ PA6-CF and all other Polymaker products. Contact us to enquire!

The typical values presented in Polymakers data sheet are intended for reference and comparison purposes only. Due to the nature of 3D printing they should not be used for design specifications or quality control purposes.

STORAGE & DRYING

Nylon filaments are very hygroscopic meaning they quickly absorb moisture from the air which can affect printing quality and strength of printed parts. Before packaging, PolyMide™ PA6-CF is dried to ensure the best printing quality and filaments are vacuum sealed in a resealable mylar bag to protect the filament from moisture.

- When opening, carefully open the resealable bag, remove the spool and close the bag back to preserve the desiccant bag.

- Print PolyMide PA6-CF from a dry box with a 10 - 15% RH which will protect the filament from absorbing moisture. We recommend Polymaker PolyBox™ which uses desiccant to keep the filament at dry conditions (relative humidity of 15% or less) without using heat. Dry boxes with a heating element can degrade plastic filaments if used extensively.

- After the print is completed, PolyMide™ PA6-CF can be stored in the PolyBox™, be sure to monitor and maintain the desiccant to keep RH below 15% RH. If a PolyBox™ is not being used the filament can be resealed in the resealable bag at the end of the print. In both situations it's recommended to store the filament away from sunlight for long term storage and replace / dry the desiccant as required.

These recommendations are ultimately to prevent the filament from absorbing moisture in the first place. If you hear popping sounds and notice that the surface quality of your print is uneven or the colour is not consistent, this is a likely indicator that the filament has absorbed too much moisture and can be remedied. Spools of PolyMide™ PA6-CF can be dried in a preheated convection oven at 80˚C for up to 12 hours.

Although drying is a suitable solution it's highly recommended not to excessively dry the filament and instead take precautions to prevent moisture absorption. Continually drying any plastic can make it more brittle and storing filament long term with moisture content can cause filaments to become more brittle due to hydrolysis.

FAQ

Q: What is the "Dry" state vs "Wet" state?

A: Nylon 6 and Nylon 12 materials absorb moisture not only as a filament but also the final printed part, we call this process moisture conditioning. The "Dry" state is the printed part immediately after annealing and the "Wet" state represents the mechanical properties after absorbing moisture from the air, there is a third state "Saturated" which represents the properties if the material is submerged in water. As the printed part absorbs moisture, it will become more flexible and impact resistant, seeing a decrease in rigidity and tensile strength when compared to its dry state.

Shorter chain nylons such as PA6 or PA6,6 are capable of absorbing more moisture compared to longer-chain nylons such as PA11 and PA12, thus longer-chain nylons show a smaller shift in characteristics between dry and wet state and shorter-chain nylons show a greater change. It is generally assumed that PolyMide™ PA6-CF 3D prints will eventually reach their "Moisture Conditioned" state however there are numerous cases where the part may never become moisture conditioned. Examples include components operating in a high temperature environment, 3D prints that have been post-processed and protected with a moisture barrier or perhaps for applications where the PolyMide™ PA6-CF is submerged in a specific chemical or oil. For high humidity applications or applications where the part may come in contact with water, PolyMide™ PA612-CF or PolyMide™ PA12-CF may be better options to consider.

Q: Can I print this material without wear resistant hardware (nozzle etc.)?

A: PolyMide™ PA6-CF contains 20% chopped carbon fibers by weight which makes it very abrasive. It is important to have an abrasion resistant nozzle and hardware when printing this material. PolyMide™ PA6-CF can easily damage a brass nozzle after a few hundred grams of printing. Hardened nozzles are more expensive than regular brass nozzle so it is important to consider the amount of materials planned to be used. For some users it may be more cost effective to destroy one nozzle for some prints, but please note users are responsible for all printer 'wear and tear'.

Q: How well does Polymakers Warp-Free™ technology perform?

A: With Polymakers Warp-Free technology, more users can effectively print PA6-CF with better dimensional stability than comparative nylon products. This technology works best when printing with low bed/chamber temperatures. Because the warping behaviour of Nylon materials is partially related to its crystallization rate while printing. If a user does print with a high temperature heated bed or chamber, the heat will increase the crystallization rate and cause a part to warp.

Q: Is annealing PolyMide™ PA6-CF required?

A: After printing, annealing PolyMide™ PA6-CF prints will ensure the highest degree of crystallinity. This is a recommended step as it allows end users to get the best properties and performance from their parts. PolyMide™ PA6-CF can be annealed in a convection oven at 80˚C for 6 hours. Of course annealing may not be required for applications that don't require the best thermal or mechanical properties. In some rare cases with fine or thin geometries, different annealing instructions or design considerations may be required for the best results.

Q: Will this filament absorb moisture?

A: Yes, Polyamides are hygroscopic, meaning that they absorb moisture from the air. Some grades are more sensitive to moisture than others but regardless it's important to keep all nylon filaments dry for the best printing process. Polymaker nylon filaments are dried from the factory to ensure customers can achieve excellent results straight away, we recommend keeping your spool of PolyMide™ PA6-CF dry as moisture can significantly reduce mechanical properties and cause print defects such as oozing and poor surface quality. To prevent moisture absorption in your filaments, it is recommended to use the PolyBox™ which provides a stable, low level humidity storage solution for filaments during and in-between printing. If PolyMide™ PA6-CF appears to have absorbed too much moisture, they can be dried in a preheated convection oven for 12 hours at 80˚C.

Q: Is PolyMide™ PA6-CF suitable for high humidity or "wet" applications?

A: PolyMide™ PA6-CF is not ideal for high humidity or wet applications requiring high stiffness or strength and is not ideal for applications where the part may be submerged in water. When submerged in water the part will become quite soft and malleable and can swell when it absorbs water. PolyMide™ PA12-CF is a far better nylon for "wet" applications due to it's lower moisture sensitivity. Less moisture absorption = less change in mechanical properties. If you require a material between nylon 6 and nylon 12, PolyMide™ PA612-CF is an excellent all-rounder.

Q: Should I rewind this filament if I want to use it with a different spool?

A: We strongly advise against tampering with the product by rewinding. See our article for full details about the risks. All Polymaker filaments are wound with tension but without strain. Rewinding completely rearranges the curvature of the winding and this strain over time can cause most plastics to catastrophically break. If for some reason your printer is locked into fitting less than standard sized spools, there may be safe printable adaptors or external mounting solutions available.

Don't know where to start? Or which filament will suit your application? We have a broad range of support options including telephone support. Contact us today!

Materials

Materials

PLA - This solid filament is used to make models that are a refined representation with rigid properties.

TPU - This flexible filament holds the shape of the model and can with stand being twisted and squashed to survive the field environment.

Shipping

Shipping

Free standard shipping and Express for free orders over $300 calculated at the checkout.

All items are shipped from Townsville, QLD.

Shipping World Wide - coming soon.

Care Instructions

Care Instructions

PLA

Temperature:

Keep it cool! PLA starts to soften at around 60°C (140°F), so avoid placing it near heat sources or leaving it in hot cars.

Sunlight:

Prolonged direct sunlight can cause fading and potential deformation. Try to keep it out of long sun exposures.

Cleaning:

Gently wash with warm water and a bit of mild soap using a soft cloth. No harsh scrubbing, please!

Handling:

Handle with care—avoid excessive bending or dropping it, as PLA is rigid and can crack or break.

Storage:

Store in a cool, dry place to maintain its shape and longevity.

TPU

Temperature:

TPU is built to be flexible, but still avoid extreme or prolonged heat. It’s more resilient than PLA, but unnecessary heat can still degrade it over time.

Sunlight:

Try not to leave TPU items in direct sunlight for too long, as UV rays can fade the colors and slowly affect the material quality.

Cleaning:

Just like PLA, a quick clean with warm water and mild soap works great. Use a soft cloth and don’t be too rough.

Handling:

Enjoy its flexibility! However, even though TPU can bend, continuous stretching or heavy impacts might wear it out faster.

Storage:

Keep it in a cool, dry spot away from harsh elements to maintain its flexibility and appearance.

Share