Spack.au

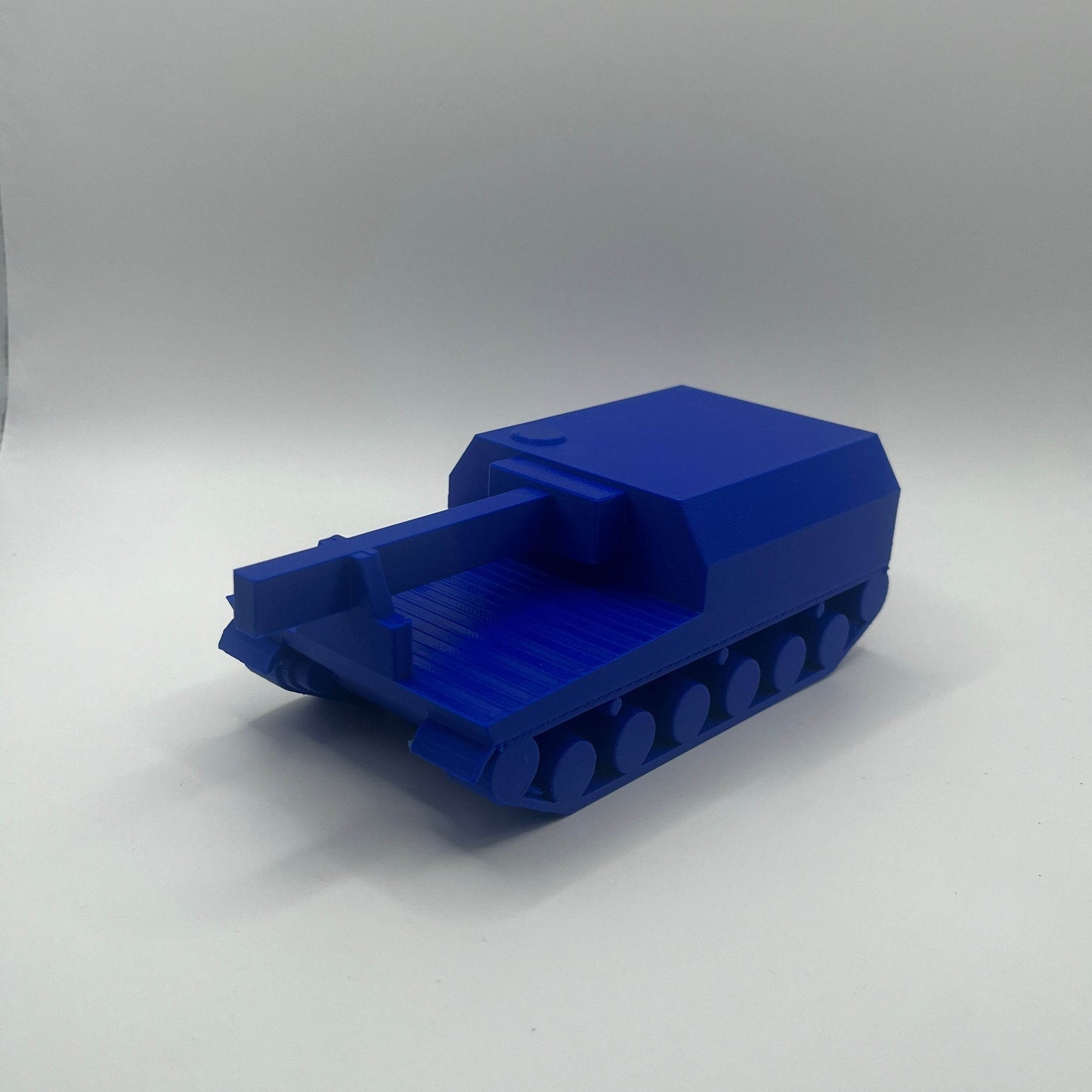

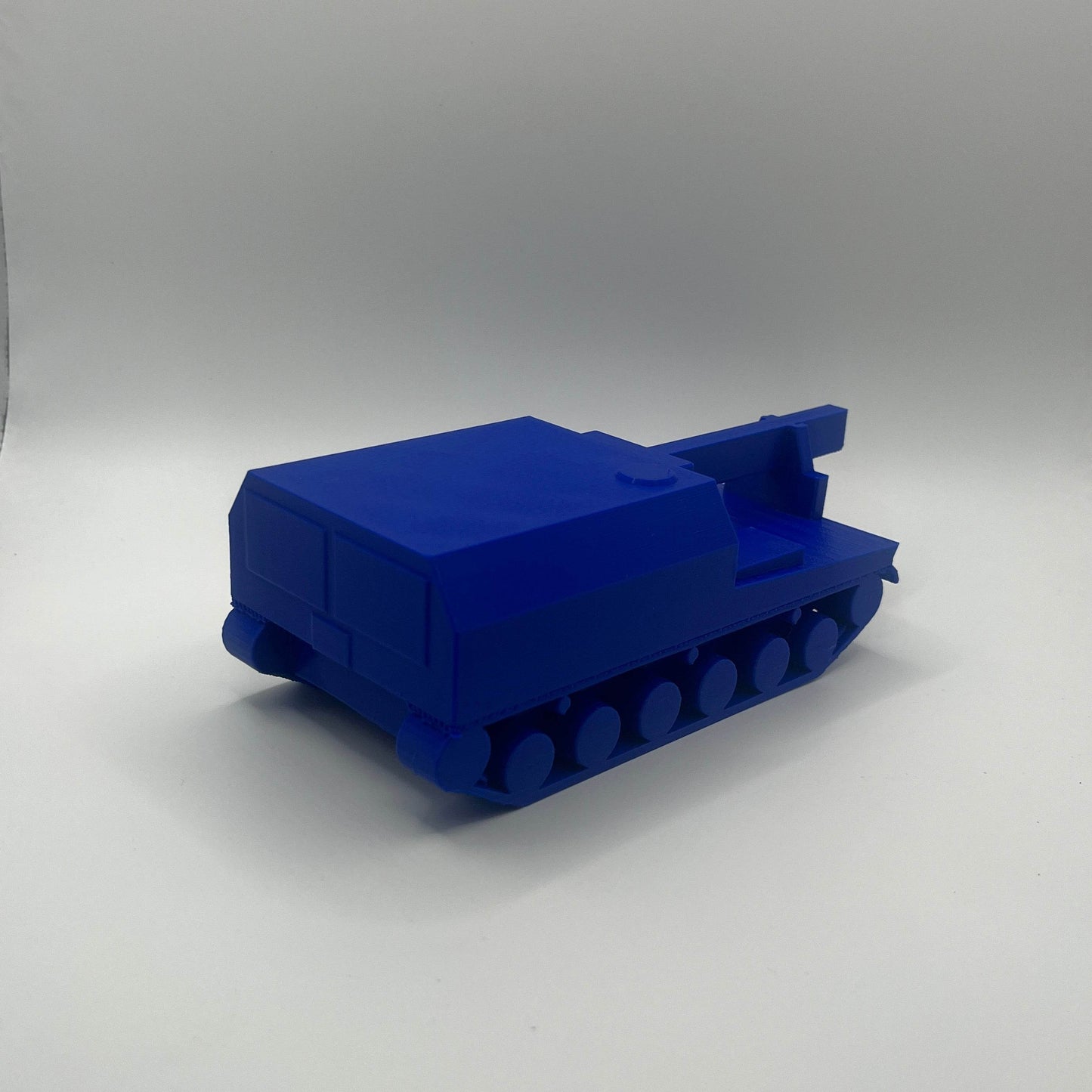

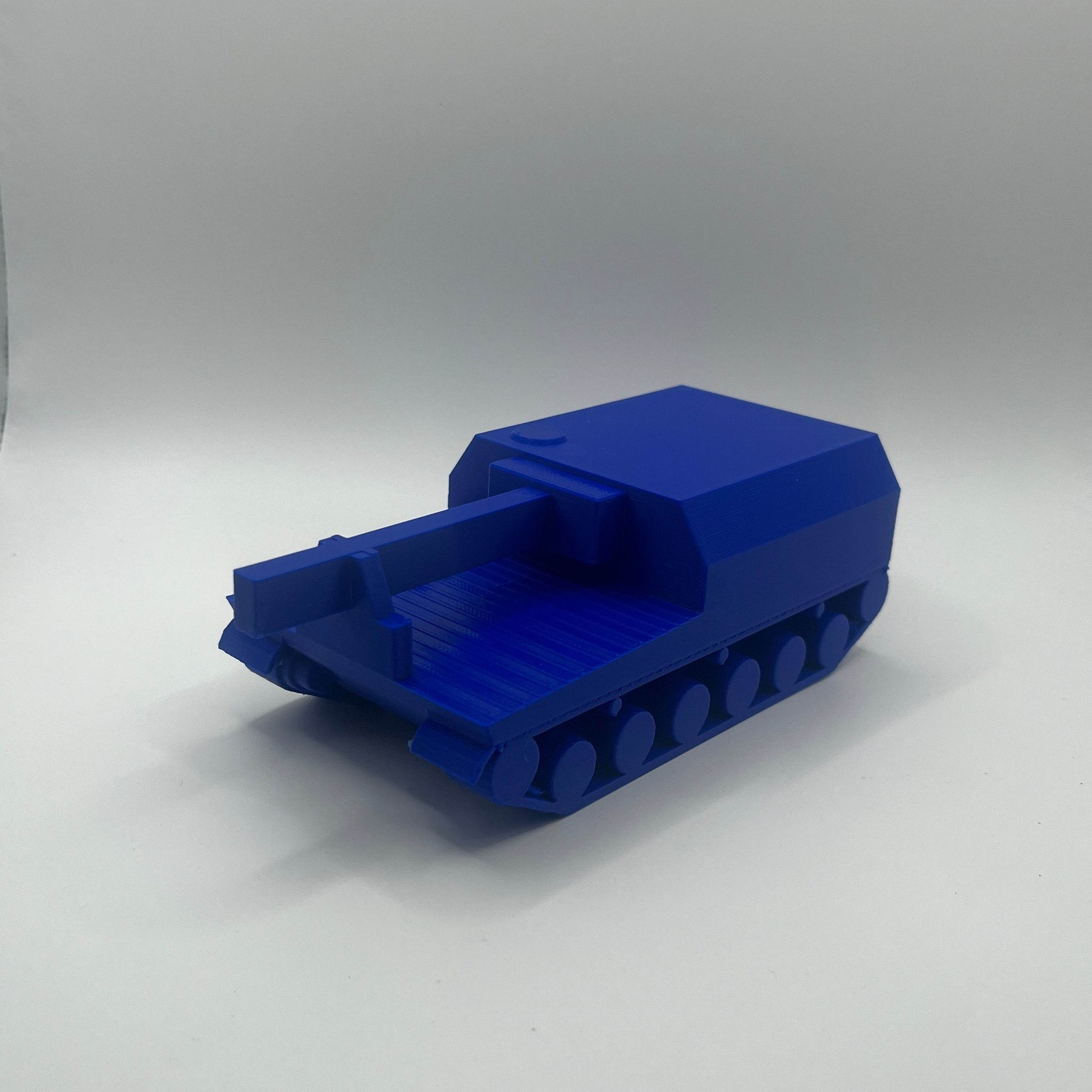

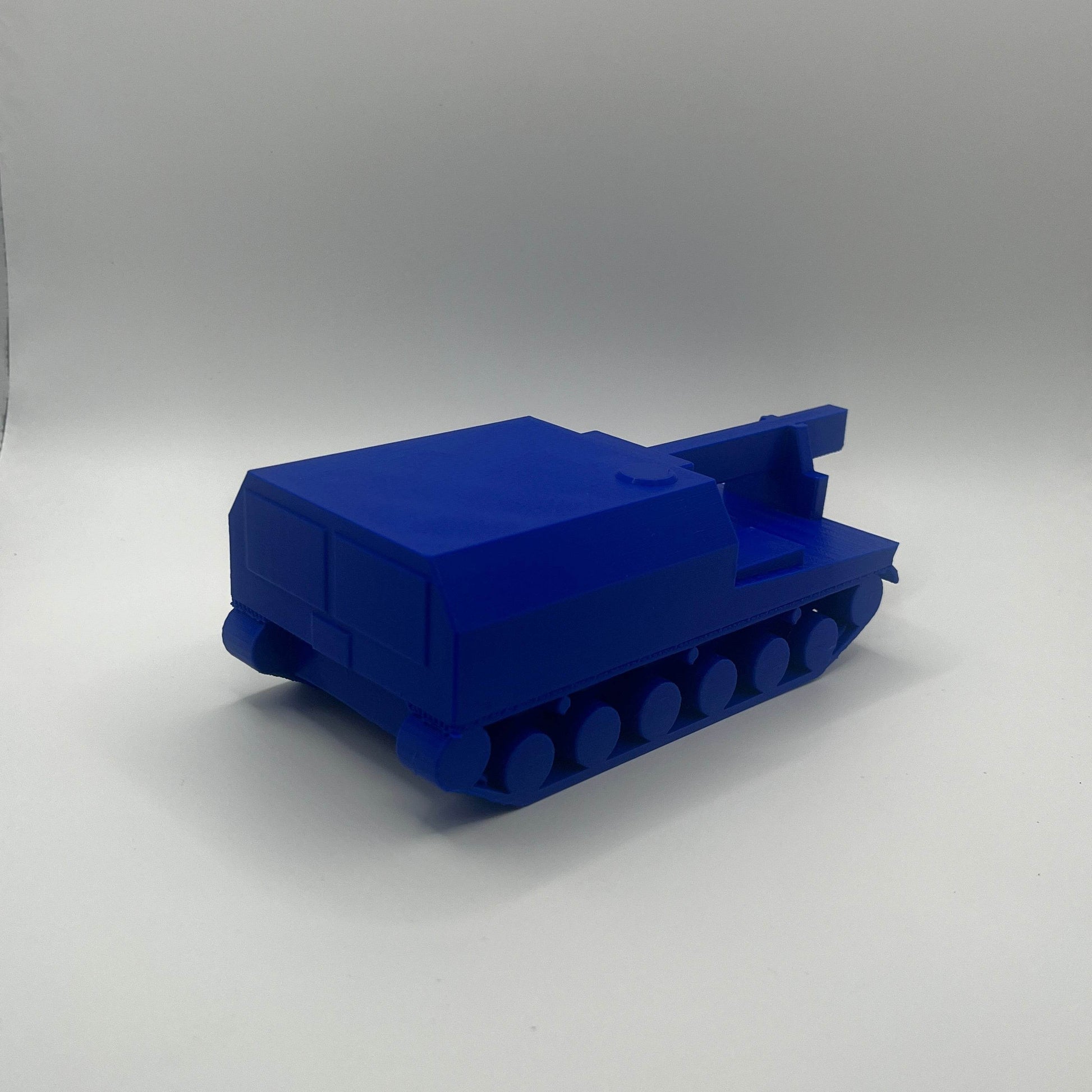

AS10 ARV

AS10 ARV

Low stock: 10 left

Couldn't load pickup availability

All models are made to order and are shipped in 1-3 business days.

Get your hands on a durable, scaled 3D printed model of an Australian Defence Force (ADF) armoured vehicle, crafted with accuracy for practical use in tactical displays and training sessions. Built with PLA and/or TPU, this mud model kit features authentic AusCam like Olive Green, Blue force (bluefor), or Red force (redfor), matching the rugged look of ADF vehicles in field exercises.

Each model is designed to meet the demands of orders groups, collectors, and educators, adding realistic detail for strategic planning, orders delivery, and Australian military displays. Ready to use right out of the box, this model is a reliable choice for terrain models and military-inspired dioramas.

Best Use: Orders groups, tactical displays, military collectors, and educational setups.

Add a piece of Australian military precision to your setup. Perfect for collectors, tactical trainers, and those interested in ADF-inspired models.

The K9 Thunder is a South Korean 155 mm self-propelled howitzer, developed by the Agency for Defense Development and private companies including Dongmyeong Heavy Industries, Kia Heavy Industry, Poongsan Corporation, and Samsung Aerospace Industries for the Republic of Korea Armed Forces. It is currently manufactured by Hanwha Aerospace. K9 howitzers operate in conjunction with the K10 Ammunition Resupply Vehicle variant.

The entire K9 fleet operated by the Republic of Korea Armed Forces is undergoing upgrades to the K9A1, with a further upgraded variant, the K9A2, in testing for production. As of 2022, the K9 series held a 52% share of the global self-propelled howitzer market since 2000.

The K9 was evaluated by the Australian military starting in April 2010, where it demonstrated compatibility with the M982 Excalibur. The Australian variant, designated AS9, is expected to include a NATO-standard fire-control system, the Battlefield Management System – Fires (BMS-F), a Remote Weapon System (RWS), and anti-tank mine protection. Its hydropneumatic suspension was enhanced to support increased weight.

Production of the AS9 and the AS10 ammunition resupply vehicle began in June 2023. In July, the Australian Army conducted ammunition compatibility tests at the Agency for Defense Development test centre in South Korea. In August, Israeli company Epsilor was selected to supply NATO-standard 6T Li-ion batteries for the howitzer.

On 28 March 2024, Hanwha Aerospace announced the start of assembly of two AS9s and one AS10 in Changwon, with the remaining 28 AS9s and 14 AS10s to be built at the H-ACE facility in Australia. On 23 August 2024, Hanwha Aerospace held an opening ceremony for H-ACE, attended by Korean and Australian government officials. The factory will begin mass production of the AS9 and AS10 this year, with all vehicles scheduled for delivery to the Australian Army by 2027.

Materials

Materials

PLA - This solid filament is used to make models that are a refined representation with rigid properties.

TPU - This flexible filament holds the shape of the model and can with stand being twisted and squashed to survive the field environment.

Shipping

Shipping

Free standard shipping and Express for free orders over $300 calculated at the checkout.

All items are shipped from Townsville, QLD.

Shipping World Wide - coming soon.

Care Instructions

Care Instructions

PLA

Temperature:

Keep it cool! PLA starts to soften at around 60°C (140°F), so avoid placing it near heat sources or leaving it in hot cars.

Sunlight:

Prolonged direct sunlight can cause fading and potential deformation. Try to keep it out of long sun exposures.

Cleaning:

Gently wash with warm water and a bit of mild soap using a soft cloth. No harsh scrubbing, please!

Handling:

Handle with care—avoid excessive bending or dropping it, as PLA is rigid and can crack or break.

Storage:

Store in a cool, dry place to maintain its shape and longevity.

TPU

Temperature:

TPU is built to be flexible, but still avoid extreme or prolonged heat. It’s more resilient than PLA, but unnecessary heat can still degrade it over time.

Sunlight:

Try not to leave TPU items in direct sunlight for too long, as UV rays can fade the colors and slowly affect the material quality.

Cleaning:

Just like PLA, a quick clean with warm water and mild soap works great. Use a soft cloth and don’t be too rough.

Handling:

Enjoy its flexibility! However, even though TPU can bend, continuous stretching or heavy impacts might wear it out faster.

Storage:

Keep it in a cool, dry spot away from harsh elements to maintain its flexibility and appearance.

Share